BLOG

What is 3D printing?

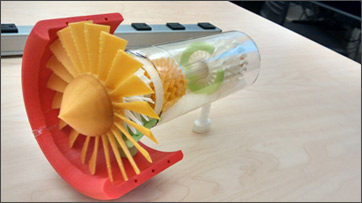

3D printing is a process of making 3D solid objects from a 3D file.It is also called as additive manufacturing process as the object is created by addition of thin layers of 16-180 microns or more.

Why 3D printing?

Due to numerous application of 3D printing in various sectors its demand is increasing day by day.

- Automobile Sectors – Automobile sector is using 3D metal printing technology for making spare parts, jigs and fixtures etc.

- Aerospace Sector – Aerospace sectors is using 3D printing technology in manufacturing high performance parts.

- Aviation Sector- Aviation sector is using 3D printing technology in making different parts of airplanes.

- Education Sectors – is using 3D printing technology in making prototypes of models to help students in better understanding of functionality.

- Construction Sector-Counties like China are using 3D printing technology to print houses.

- Medical Sector- is using 3D printing technology in making 3D pens for orthopedic surgery and 3D printed implants for better patient care.

Image Courtesy: Wikipedia

Image Courtesy: Wikipedia

How does 3D printing work?

There are basically 3 main steps in 3D printing-

- Preparation of 3D model- A 3D model is created with the help of a 3D modelingsoftware such as SolidWorks, Fusion 360, Rhinoceros etc. This 3D model is the sliced into 2D layers with the help of printer software and then converted into a coding language.

- Printing Process –The second step of printing process is further sub categorized into 2 steps-

- Choosing of appropriate material – You need to choose the best material for your object which fulfills its properties. There are variety of materials used for 3D printing such as - plastics, ceramics, resins, metals, sand, textiles, biomaterials, glass etc.

- Choosing appropriate printer- Depending on the size of the object & material select the best suitable printer for printing. It usually takes 4-20 hours' time to complete a 3D print.

Below are the few printing technologies summarized -

FDM Printing Technology – It is the most common printing method used due to number of printers available in the market. It is mostly preferred by individuals. FDM is an affordable printing technology when compared to other technologies.

SLS Technology - It is a 3d printing technology in which fabrication of object is done by melting successive layers of powder together in the form of an object. It is suitable for Plastic and Alumide material.

SLA Technology - This technology uses a photopolymer resin for printing. In this a UV laser is used to cure photopolymer resin.

DLP Technology – Digital light Processing is a similar method to SLA technology except that here we use safelight to cure photopolymer resin instead of UV laser.

Multi-Jet Printers - Similar to SLS Technology, the high-quality PolyJet and MultiJet 3D printing processes use a UV light to crosslink a photopolymer.

- Finishing Process – 3D printed parts are hardly ready to use. They need finishing before finally delivering the object.It is sanded, lacquered or painted to complete it as per requirement.

Advantages of 3D printing

- Start up cost is very low

- There is geometric complexity at no extra cost

- Easy to customize the parts.

Limitations of 3D printing

- Low strength

- Costly for high volume production

- Limited accuracy

Architecture / BIM

Architecture / BIM Drafting

Drafting Floor Plan

Floor Plan Shop Drawing

Shop Drawing MEP

MEP Mechanical / Industrial

Mechanical / Industrial Automobile Designs

Automobile Designs Solar Design

Solar Design Graphic Design

Graphic Design